Uncategorized

Not All Chains Are Created Equal: A Simple Guide to Choosing the Right Steel Chain for Your Heavy-Duty Job

You have a heavy job to do. Maybe you need to tow a small vehicle, haul fallen trees, or secure heavy equipment to a trailer. You know you need a strong chain, but when you look at the options—1/8 inch, 3/16 inch, 1/4 inch, stainless steel, galvanized steel—the choice can be confusing. Picking the wrong chain isn’t just inefficient; it can be dangerous.

This guide will break down the three most important factors you need to consider—load limit, diameter, and material—to ensure you choose the right chain with confidence.

1. The Most Important Factor: Working Load Limit (WLL)

Before looking at anything else, you must understand the Working Load Limit. The WLL is the maximum mass or force that a chain is certified to handle safely. It is not the same as breaking strength, which is the point at which the chain will fail under load. For safety, the WLL is always significantly lower than the breaking strength.

Rule of Thumb: Always choose a chain with a WLL that exceeds the weight of the heaviest object you plan to lift, pull, or secure. Never use a chain for a load that is heavier than its stated WLL. Safety always comes first.

2. It’s All in the Diameter: How Size Affects Strength

The thickness, or diameter, of the chain’s links is the most direct indicator of its strength. A small increase in diameter results in a large increase in strength and WLL.

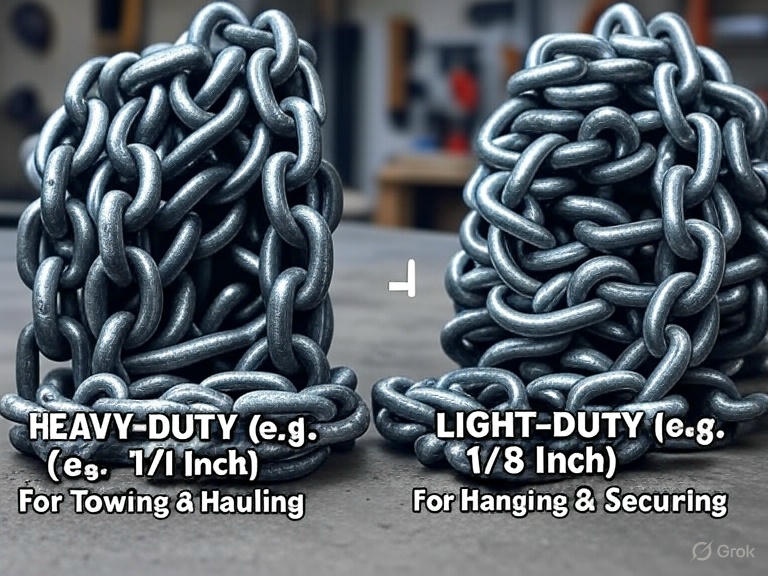

- Light-Duty Chains (e.g., 5/64 to 1/8 Inch): These thinner chains, often called jack chains, are not suitable for towing or hauling. Their job is hanging and securing light objects. Think hanging a fluorescent light fixture, a decorative basket, or creating a lightweight barrier.

- Medium-Duty Chains (e.g., 5/32 to 3/16 Inch): This is a versatile middle ground. These chains are excellent for jobs like securing a canoe to a roof rack, hanging heavy-duty shop lights, creating swing set seats, or as a security chain for a gate. They offer a significant step up in strength from light-duty chains.

- Heavy-Duty Chains (e.g., 1/4 Inch and Up): This is the category for serious work. A 1/4-inch coil chain is built for demanding tasks. These are the chains you use for light-duty towing, securing heavy cargo, hauling logs, or anchoring larger items. When the job involves significant weight and risk, you need a heavy-duty diameter.

3. Material Matters: Stainless Steel vs. Galvanized Steel

Once you know the strength you need, the final choice is the material, which depends entirely on the environment where the chain will be used.

- Stainless Steel: The primary advantage of stainless steel is its superior resistance to rust and corrosion. Its chromium content creates a passive, non-rusting film on the surface. This makes it the perfect choice for marine environments (on boats or docks), food-grade applications, or any outdoor use where a clean, rust-free appearance is desired for years to come, like architectural installations.

- Galvanized Steel: Galvanized chain has been hot-dipped in a protective zinc coating. This zinc layer makes the chain incredibly durable and resistant to abrasion and corrosion, though it may develop a dull, white oxidation over time instead of red rust. It is a true workhorse, ideal for construction, agriculture, and general towing where the chain will be subjected to rough use and abuse.

By evaluating your task based on these three factors—Working Load Limit, Diameter, and Material—you can move past the confusion and select the perfect chain that is both safe and perfectly suited for your project.